Processing of Oil

THE OIL-MAKING PROCESS

Environmental and economic requirements led, during the early ‘90s, to the perfection of a new-generation centrifugal extraction system, that was capable of eliminating the issues associated with vegetation water.

This type of extraction, known as the “two phase” or “integral method”, makes it possible to eliminate the use of process water, so indispensable in the three-phase system, with the double advantage of limiting the use of natural resources (water) and eliminating the production of waste water, whose disposal adds considerably to the running costs of olive mills.

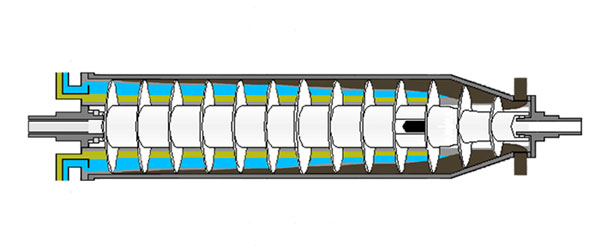

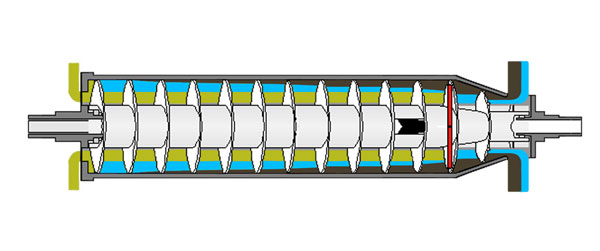

In two-phase extraction, the horizontal centrifuge is designed to have only two exits, so that the vegetation water is expelled together with the solid waste (pomace) while the oil is expelled from the other end. From here, via the vibro-filter compartment, the oil mixture is channelled into a single vertical centrifuge. Therefore the only by-product that is obtained is a very wet pomace (with about 65% water content).

The principal feature of this system is the oil is extracted from the olive paste without the addition of water. Only if the olives happen to be too dry is 5% of water added, to reach the correct water content.

The addition of process water in the three-phase system results in more oil being lost in the pomace, therefore a lower extractive yield, the production of large quantities of vegetation water to be disposed of with consequent issues of both economic and environmental nature and a lower quality of production, mainly linked to the lower content of polyphenols in the oil obtained.

If process water is not added, on the other hand, a better quality of oil is obtained with lower environmental impact (thanks to the lesser quantity of vegetation water produced) and lower investment and operating costs, the latter due to reduced consumption of water and energy.